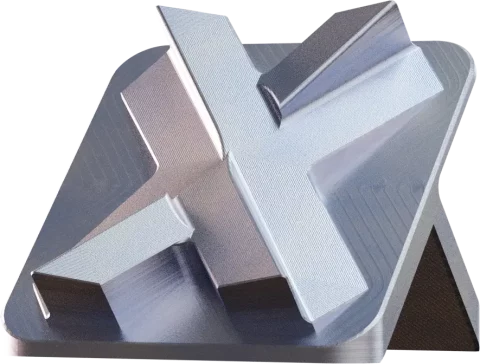

التصنيع الآلي باستخدام الحاسب الآلي

التصنيع الآلي باستخدام الحاسب الآلي

- لا يوجد موك، من 1 قطعة إلى أكثر من 5000 قطعة

- تفاوت يصل إلى 0.001 بوصة.

- اختر من بين أكثر من 100 خامة وأكثر من 20 تشطيب سطح.

ابدأ مشروع CNC جديد!

طلب التصنيع الآلي باستخدام الحاسب الآلي: كيف يعملالطلب

1. طلب التصنيع

ارفع تصميماتك واختر الكمية والخامة وخيارات الألوان.

2. اقتباس

نقوم بإجراء تحليل التصميم مقابل التصنيع وإعداد عرض الأسعار الخاص بك في غضون 48 ساعة.

3. التسليم

قدم طلبك واحصل على قطع الغيار.

مواد التصنيع الآلي باستخدام الحاسب الآلي

يستخدم القولبة بالحقن مجموعة كبيرة من المواد البلاستيكية، مما يجعلها مثالية للعديد من التطبيقات في كل الصناعات تقريبًا. يمكننا الحصول على آلاف المواد عند الطلب.

سيراميك الألومينا | يتم تقدير سيراميك الألومينا لصلابته العالية وثباته الحراري ومقاومته للتآكل والتآكل. وتُستخدم في تطبيقات مثل العوازل الكهربائية وأدوات القطع والأجهزة الطبية الحيوية. |

|---|---|

ألومنيوم | يُستخدم الألومنيوم على نطاق واسع في التصنيع الآلي نظرًا لكثافته المنخفضة وخصائصه الميكانيكية الممتازة وموصلية حرارية وكهربائية عالية ومقاومته للتآكل. تُستخدم مواد سبائك الألومنيوم بشكل أساسي في صناعات الطيران والسيارات والبناء والبحرية والإلكترونيات والتعبئة والتغليف والسلع الطبية والاستهلاكية نظرًا لخصائصها الممتازة. |

فولاذ الأدوات | صُمم فولاذ الأدوات من أجل الصلابة العالية، ومقاومة التآكل، والقدرة على الاحتفاظ بحافة القطع في درجات الحرارة المرتفعة، مما يجعله مثاليًا لقطع وتشكيل المواد الأخرى. يشيع استخدامه في تصنيع الأدوات والقوالب، ويحتوي فولاذ الأدوات عادةً على عناصر مثل التنجستن والموليبدينوم والكروم والفاناديوم. تعمل هذه العناصر على تعزيز صلابته ومقاومته للحرارة، مما يجعله مناسبًا لتطبيقات مثل الختم والبثق وتشكيل المعادن الأخرى. |

الفولاذ المقاوم للصدأ | يشتهر الفولاذ المقاوم للصدأ بمقاومته الممتازة للتآكل وقوته ومظهره الجمالي. ويشيع استخدامه في مجموعة واسعة من التطبيقات، بما في ذلك أدوات المطبخ والأدوات الطبية ومكونات السيارات ومواد البناء. |

نحاس | يتميز النحاس الأصفر بقابلية ممتازة للتشغيل الآلي ومقاومة التآكل والتوصيل الحراري. ويُستخدم بشكل شائع في السباكة والتطبيقات الكهربائية وأدوات الزينة نظراً لمظهره الشبيه بالذهب اللامع. |

النحاس | يتميز النحاس بتوصيله الكهربائي والحراري العالي، مما يجعله ضرورياً في الأسلاك الكهربائية والإلكترونيات والمبادلات الحرارية. كما أنه يتميز بمقاومة جيدة للتآكل وقابلية التشغيل الآلي. |

تيتانيوم | يشتهر التيتانيوم بنسبة قوته العالية إلى وزنه ومقاومته للتآكل وتوافقه الحيوي. ويُستخدم على نطاق واسع في صناعة الطيران والزراعات الطبية والتطبيقات عالية الأداء. |

فولاذ التنجستن | يُعرف فولاذ التنغستن، أو كربيد التنغستن، بصلابته الشديدة ومقاومته للتآكل. ويُستخدم في أدوات القطع ومعدات التعدين والتطبيقات التي تتطلب متانة عالية. |

التصنيع الآلي باستخدام الحاسب الآلي للبلاستيك

يستخدم القولبة بالحقن مجموعة كبيرة من المواد البلاستيكية، مما يجعلها مثالية للعديد من التطبيقات في كل الصناعات تقريبًا. يمكننا الحصول على آلاف المواد عند الطلب.

بوم | POM (بولي أوكسي ميثيلين) هو بلاستيك هندسي عالي الصلابة ومنخفض الاحتكاك معروف بثبات أبعاده الممتاز ومقاومته للتآكل، مما يجعله مثاليًا للقطع الدقيقة مثل التروس والمحامل. |

|---|---|

نايلون MC نايلون | نايلون MC (النايلون المصبوب الأحادي) يوفر قوة ميكانيكية عالية وصلابة ومقاومة للتآكل، ويستخدم على نطاق واسع في التطبيقات الصناعية مثل التروس والمحامل والبكرات. |

بولي كلوريد الفينيل | PVC (كلوريد البوليفينيل) هو بلاستيك متعدد الاستخدامات وفعال من حيث التكلفة ويتميز بمقاومة جيدة للمواد الكيميائية والمتانة، ويستخدم عادةً في البناء للأنابيب والتجهيزات وإطارات النوافذ. |

بيك | PEEK (بولي إيثر كيتون بولي إيثر كيتون) هو بلاستيك حراري عالي الأداء يتمتع بمقاومة كيميائية ممتازة وخصائص ميكانيكية وثبات حراري ممتاز، وهو مناسب للتطبيقات الفضائية والطبية والصناعية. |

PA6 | PA6 (البولي أميد 6 أو النايلون 6) هو بلاستيك قوي ومتين ذو مقاومة جيدة للتآكل والمتانة، ويُستخدم عادةً في مكونات السيارات والأجزاء الصناعية والمنسوجات. |

UHMW | يشتهر البولي إيثيلين فائق الوزن الجزيئي (UHMW) بقوته الاستثنائية في الصدمات، وانخفاض الاحتكاك، ومقاومته الممتازة للتآكل، وهو مثالي لشرائط التآكل، وقضبان التوجيه، والبطانات. . |

الألياف الزجاجية | توفر المواد البلاستيكية المقواة بالألياف الزجاجية نسبًا عالية من القوة إلى الوزن، وخصائص عزل حراري وكهربائي ممتازة، وتستخدم على نطاق واسع في صناعات البناء والسيارات والفضاء. |

بولي كربونات | البولي كربونات عبارة عن بلاستيك قوي وشفاف ذو مقاومة عالية للصدمات ووضوح بصري، ويستخدم في تطبيقات مثل عدسات النظارات والأجهزة الطبية ومعدات الحماية |

تفلون | يُعرف التفلون (PTFE) بمقاومته الكيميائية الاستثنائية وانخفاض احتكاكه وثباته في درجات الحرارة العالية، وهو مثالي للطلاءات المانعة للالتصاق وموانع التسرب والحشيات. |

|---|---|

المطاط | توفر المواد المطاطية مرونة ممتازة ومقاومة ممتازة للتآكل وقوة تأثير، وتستخدم في منتجات مثل الأختام والحشيات والإطارات والخراطيم المرنة. |

باكليت | الباكليت عبارة عن راتنج الفينول فورمالدهايد المتصلد بالحرارة ذو خصائص عزل كهربائي ممتازة ومقاومة للحرارة، ويستخدم في العوازل الكهربائية وأغلفة الراديو والهاتف وأدوات المطبخ. |

|

خيارات التشطيب للتصنيع الآلي باستخدام الحاسب الآلي

السفع بالخرز

تفريغ الأجزاء مع السفع بالخرز. تكون الأجزاء النهائية ذات ملمس محبب قليلاً مع مظهر غير لامع يشبه الساتان.

الأنودة (النوع الثاني)

يوفر الأنوديز من النوع الثاني مقاومة أكبر للتآكل ويمكن استخدامه كقاعدة للطلاء والتشطيبات الأخرى.

طلاء المسحوق

يوفر لمسة نهائية لونية واقية ومستمرة على الأجزاء باستخدام طلاء معالج بالحرارة يتم تطبيقه بالتساوي. وعادةً ما تكون اللمسة النهائية أكثر صرامة ومتساوية مقارنةً بالطلاء التقليدي. يمكن طلاء المعادن مثل الألومنيوم والصلب بكفاءة باستخدام مساحيق البوليمر.

التلميع الكهربائي

عملية كهروكيميائية تعمل على تنظيف الأجزاء الفولاذية لتقليل التآكل وتحسين المظهر من خلال جعل المعدن أكثر إشراقاً.

التخميل

طلاء عديم اللون يعمل على تحسين مقاومة التآكل للسلسلة 200 و300 والفولاذ المقاوم للتآكل المتصلب بالترسيب عن طريق إزالة الحديد الحر من السطح.

الطلاء بالنيكل عديم النيكل الكهربائي

يوفر الطلاء بالنيكل عديم الإلكتروليترول طلاء نيكل موحد، مما يوفر الحماية من التآكل والأكسدة والتآكل على الأسطح غير المنتظمة.

الطلاء بالذهب

يوفر طلاء الذهب مقاومة جيدة للتآكل والتلطيخ. يتميز الذهب بمقاومة منخفضة للتلامس وتوصيلية ممتازة وقابلية لحام ممتازة.

التلميع الكهربائي

طلاء الزنك / الجلفنة ينطوي الطلاء بالزنك على الترسيب الكهربائي لطلاء رقيق من معدن الزنك على سطح جسم معدني آخر، يُعرف باسم الركيزة. يخلق طلاء الزنك حاجزاً فيزيائياً يمنع الصدأ من الوصول إلى السطح المعدني الأساسي.

التصنيع الآلي باستخدام الحاسب الآلي لمختلف الصناعات

توفر خدمة تصنيع الصفائح المعدنية لدينا مكونات مخصصة وعالية الدقة لمختلف الصناعات، مع التركيز على الجودة والمتانة والأداء الموثوق به.

الطيران والفضاء

السيارات

الأتمتة

الأجهزة الطبية

الروبوتات

المنتجات الاستهلاكية

اطلب قطع غيار ماكينات التصنيع باستخدام الحاسب الآلي الآن

التركيز على معالجة الأجزاء الدقيقة

اتصل بنا

رقم 1,

info@chuanghuicraft.com

+86 17722344847